The Industrial Internet of Things (IIoT) creates completely new sales areas and business models for companies. The prerequisite for lasting success is a data-based configuration of what can be optimized and how this can be done. With the assistance of customized use cases, IIoT-Guidance helps companies identify their untapped potential and profitably capitalize on it.

iMOUSE: Integrated monitoring & operation system in use within a standardized environment

The aim of the iMouse project is to provide end-to-end automated monitoring of laboratory animals housed in standard cages. This system will be completely integrated into the existing workflows at VTH. As a result, a significant improvement in animal welfare will be achieved and more efficient as well as transparent research will be possible.

Portable Hire Equipment by example filter systems: Added value through transparency

A world-leading manufacturer of filtration systems is facing an obstacle: The filtration materials meet the highest quality standards - but monitoring and replacement are done manually by the customer.

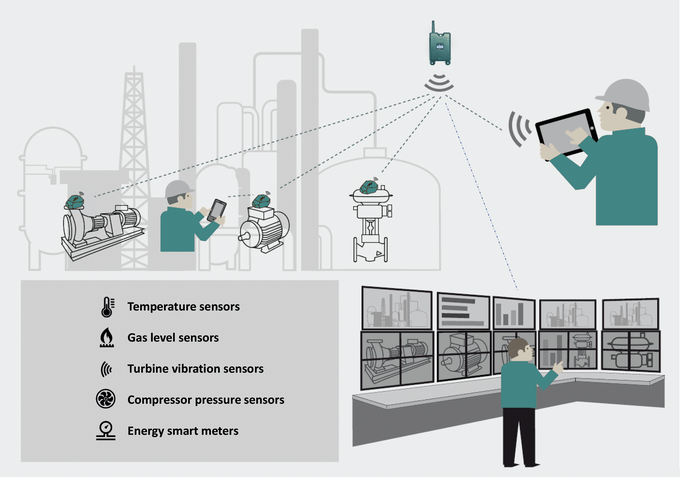

Beacon/ RHT sensor for the simplification of O&M

Sensors send their measurement data via Bluetooth or wired to a gateway. In this way, previously non-existent data can be collected and made available for use in optimization of digital processes for example.

Track & trace of mobile assets under Ex conditions

The oil, gas and chemical industries produce and transport huge quantities of valuable but also dangerous goods worldwide. Today, companies lack the transparency in the supply chain to determine.

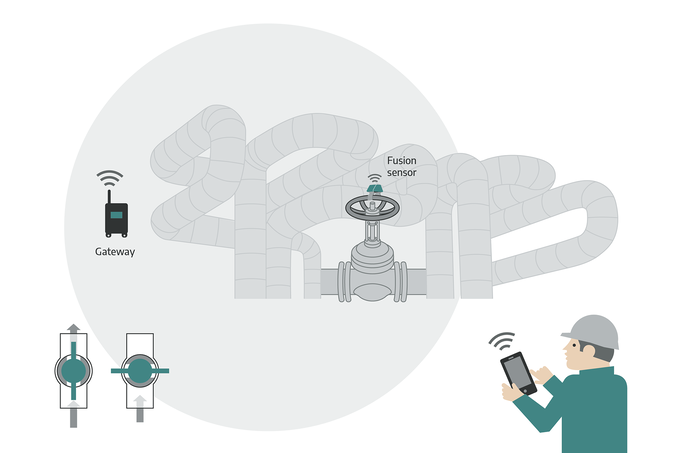

Valve position monitoring

There is a large number of manual valves in process plants, many existing plants have been working successfully and effectively with them for a long time. Valve positions are increasingly monitored in order to optimise process operation and prevent operating errors.

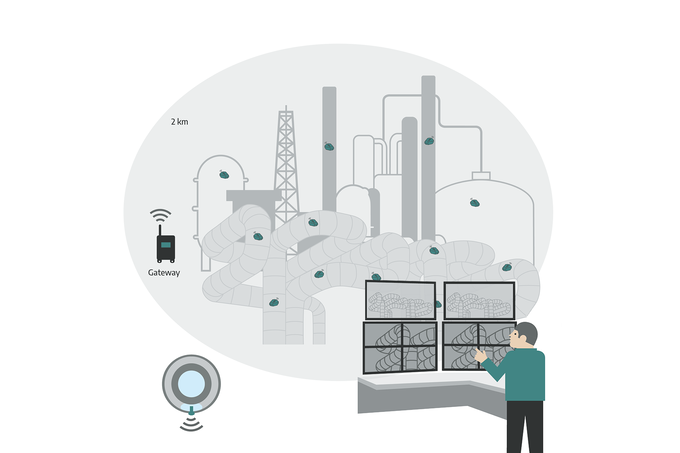

Corrosion monitoring of pipelines

The corrosion monitoring of pipelines for perfect function is an essential prerequisite for the availability, performance and safety of plants. The quality management of these pipe systems includes a systematic analysis of the actual condition. This is done today by visual inspection and mainly during plant shutdowns. Digital monitoring holds great potential for service companies and ultimately for the operator / owner.

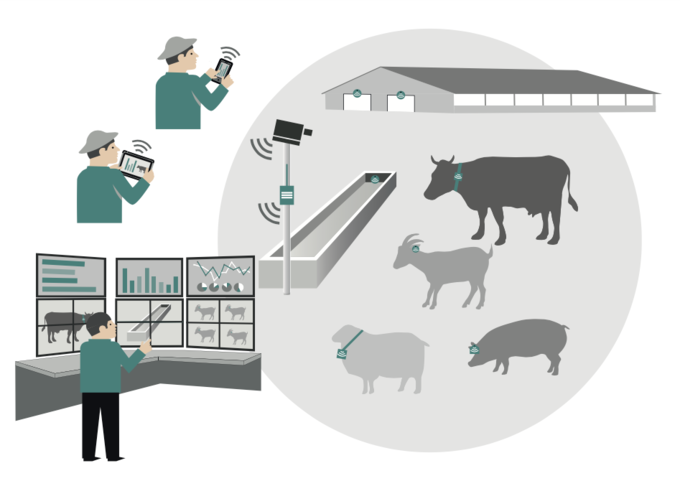

Herd management in livestock production

Optimisation of husbandry conditions and early detection of diseases through individual animal monitoring.

Network now!

You want to benefit from our know-how, our network and our independence? Then write us an e-mail, give us a call or come by for a personal meeting - together we will develop the future with you!