The challenge

The oil, gas and chemical industries produce and transport huge quantities of valuable but also dangerous goods worldwide. Today, companies lack the transparency in the supply chain to determine where the goods are or where their capital is, and whether there are transport disruptions or dangerous situations can arise. To create this transparency, SAVVY has developed a standard solution for the following applications:

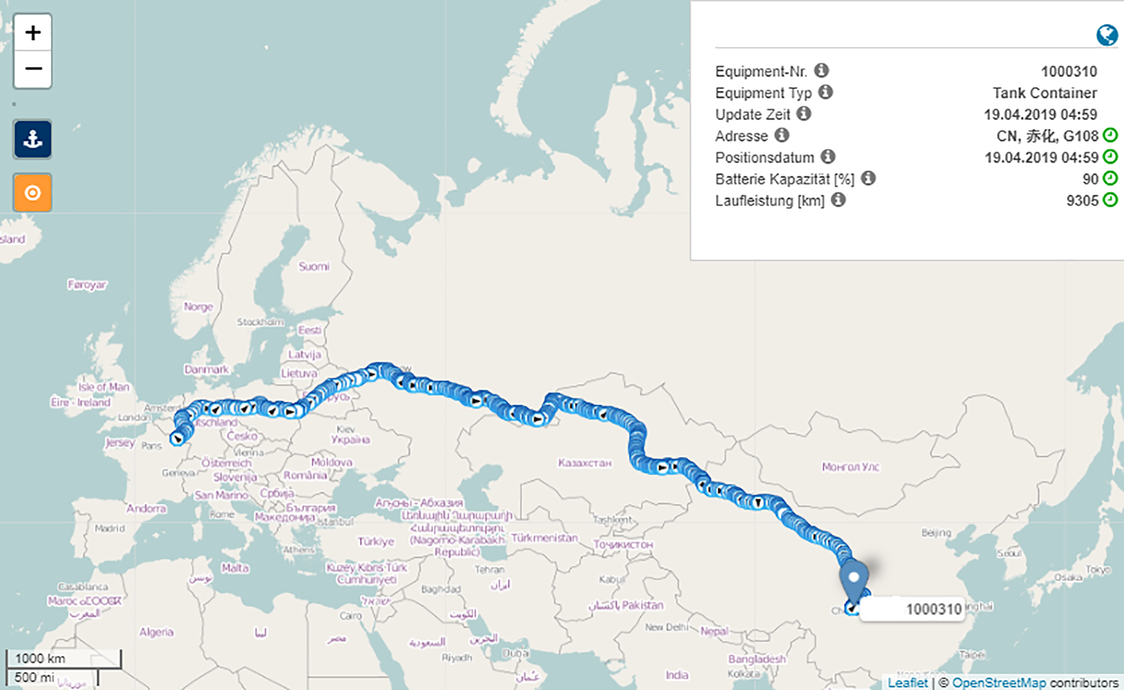

The user monitors the process parameters of the product, the plant and the supply chain in real time - in stationary and especially decentralized plants as well as in globally mobile containers (rail freight cars, tank containers and containers) - under the harshest and potentially explosive conditions. This is to ensure the safety and availability of product and plant at all times.

The user is automatically informed of any deviation of the process parameters from the expected state. Current and historical values can be viewed worldwide via an online portal or can be integrated into the user’s ERP system or shared with external parties.

The advantages:

The SAVVY® CargoTrac-ExR-M1 telematics device is allowed to travel in danger zones with potentially explosive atmospheres, because the telematics device is approved in accordance with Directive 2014/34/EU for potentially explosive areas in zones 1 (gas group IIC) and 21 (dust group IIIC) and is also IECEx-certified.

- Transparency in the supply chain for the consignor and the consignee as well as for all service providers involved in transportation

- Estimated time of arrival (ETA) determination

- Hazard detection thanks to sensor technology

- Predictive maintenance thanks to on-board vibration analysis

- Localisation of damage to product or container

- Increased plant and container availability

- Reduction of failures thanks to immediate intervention options

- Convenient monitoring directly in the customer’s control system (integrated via standardised interfaces)

- Convenient monitoring directly in the SAVVY Synergy Enterprise web portal

- Reliable and secure global data transmission

- Simple and fast installation / retrofit even during operation