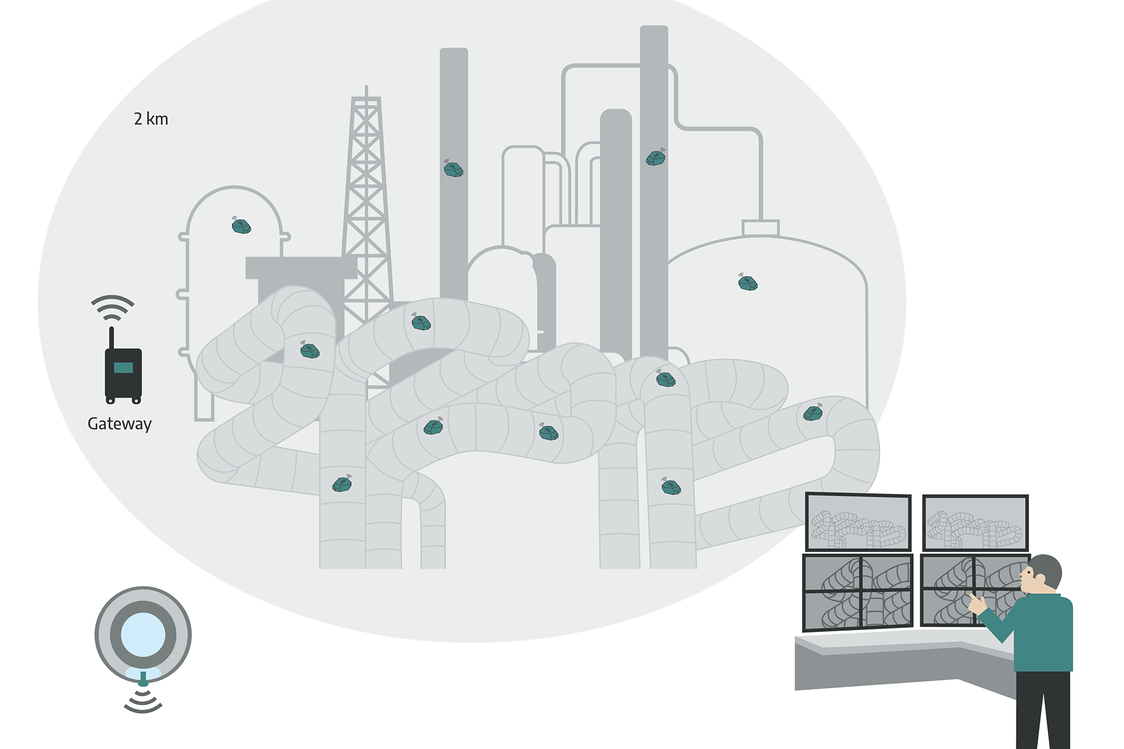

The corrosion monitoring of pipelines for perfect function is an essential prerequisite for the availability, performance and safety of plants. The quality management of these pipe systems includes a thorough analysis of the actual condition. This is done today by visual inspection and mainly during plant shutdowns. Digital monitoring holds great potential for service companies and ultimately for the operator / owner.

For this purpose, sensors are installed between the insulation and the pipeline. They send the position / temperature and humidity to a gateway via Bluetooth. Here, the data is collected and sent to the control room or to an evaluation system in the cloud. Using suitable algorithms, the corrosion can now be viewed as a function of ambient temperature and process.

The result:

- Simple and fast installation / retrofit

- Reliable data transmission

- Greater plant availability through continuous monitoring

- Reduction of failures thanks to transparency

- Savings on manual, expensive tests through automatic measurements

- Convenient monitoring of pipeline parts directly in the control system